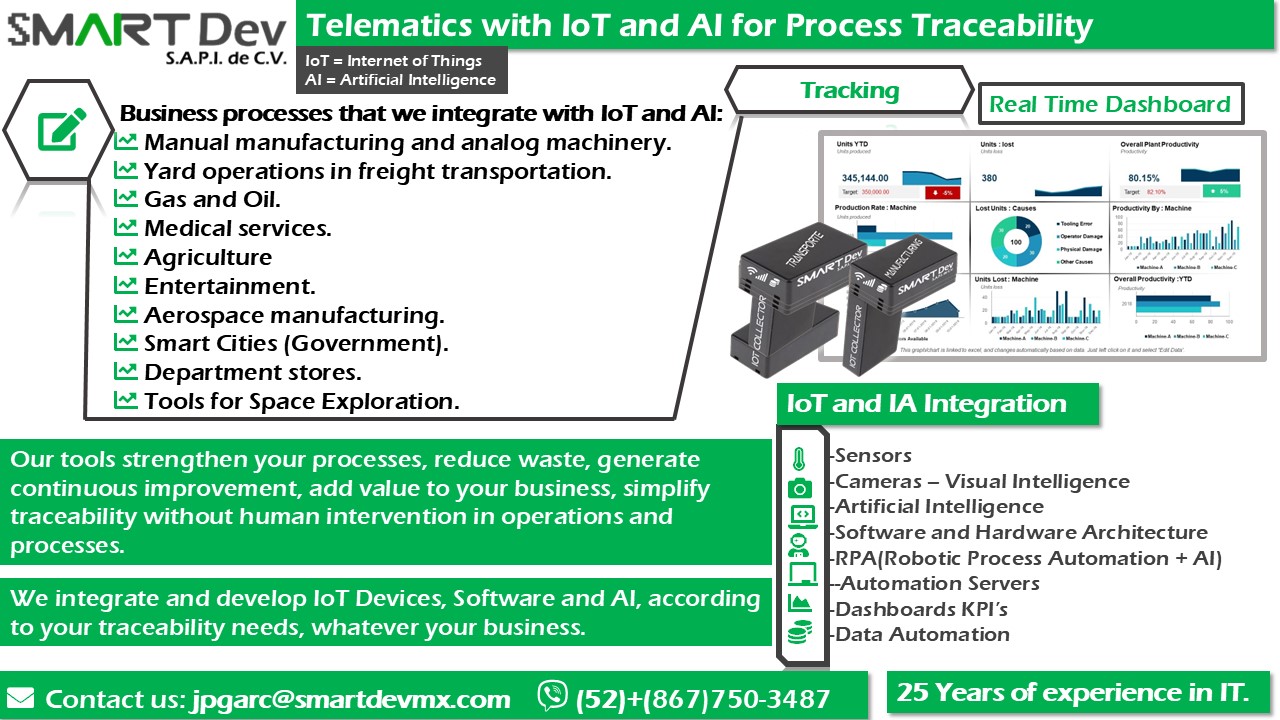

Analog to Digital

The data you generate every day is valuable information that can give you insight into your business, service, or manufacturing process, helping you make better decisions.

I+D

Our I+D department can help develop or convert your analog products to smart factory process.

Methodologies, Experience and Knowledge.

Our team specializes in IoT, Extract data, based on research, we determine the best solution to transform the data in statistics.

Solutions with IoT and IA

1.Predictive Maintenance

Machine Learning Algorithms: Analyze sensor and telemetry data to predict equipment failures, enabling proactive maintenance and reducing downtime.

Digital Twins: Virtual replicas of physical assets simulate real-time behavior, allowing AI to detect anomalies and predict failures.

Generative AI: Generates synthetic failure data to train predictive models, enhancing accuracy in forecasting maintenance needs.

2. AI-IoT Enhanced Quality Control

Computer Vision Systems: Detect defects in products using image/sensor data analysis, improving accuracy over manual inspections.

Machine Learning: Trained on labeled datasets to classify defects automatically, ensuring consistent product quality and safety.

3.Supply Chain Optimization

Demand Forecasting: Analyzes sales, customer behavior, and external factors (e.g., weather) to predict trends and adjust production.

Inventory Management: AI balances stock levels using real-time tracking, optimizing lead times and reducing costs.

4.Tracking Analog Process and Machinery

Sensors in process and operations: Adapt to dynamic environments, operate continuously, and reduce errors in tasks like assembly.

, improving efficiency in every production cell.

Robotic Process Automation (RPA): Automates administrative tasks (e.g., data entry, invoicing) using AI-driven decision-making.

5.AI-Driven Training and Assistance

Digital Work Instructions: AI tools convert speech-to-text or segment instructional videos into step-by-step guides, reducing manual effort.

Enhanced Productivity: Workers focus on high-value tasks while AI handles documentation and training processes.

Overall Impact: AI transforms manufacturing into smarter, more efficient operations by minimizing downtime, cutting costs, improving quality, and enabling agile supply chains. Its integration with IoT and IA to generate data analytics drives innovation across the industry.

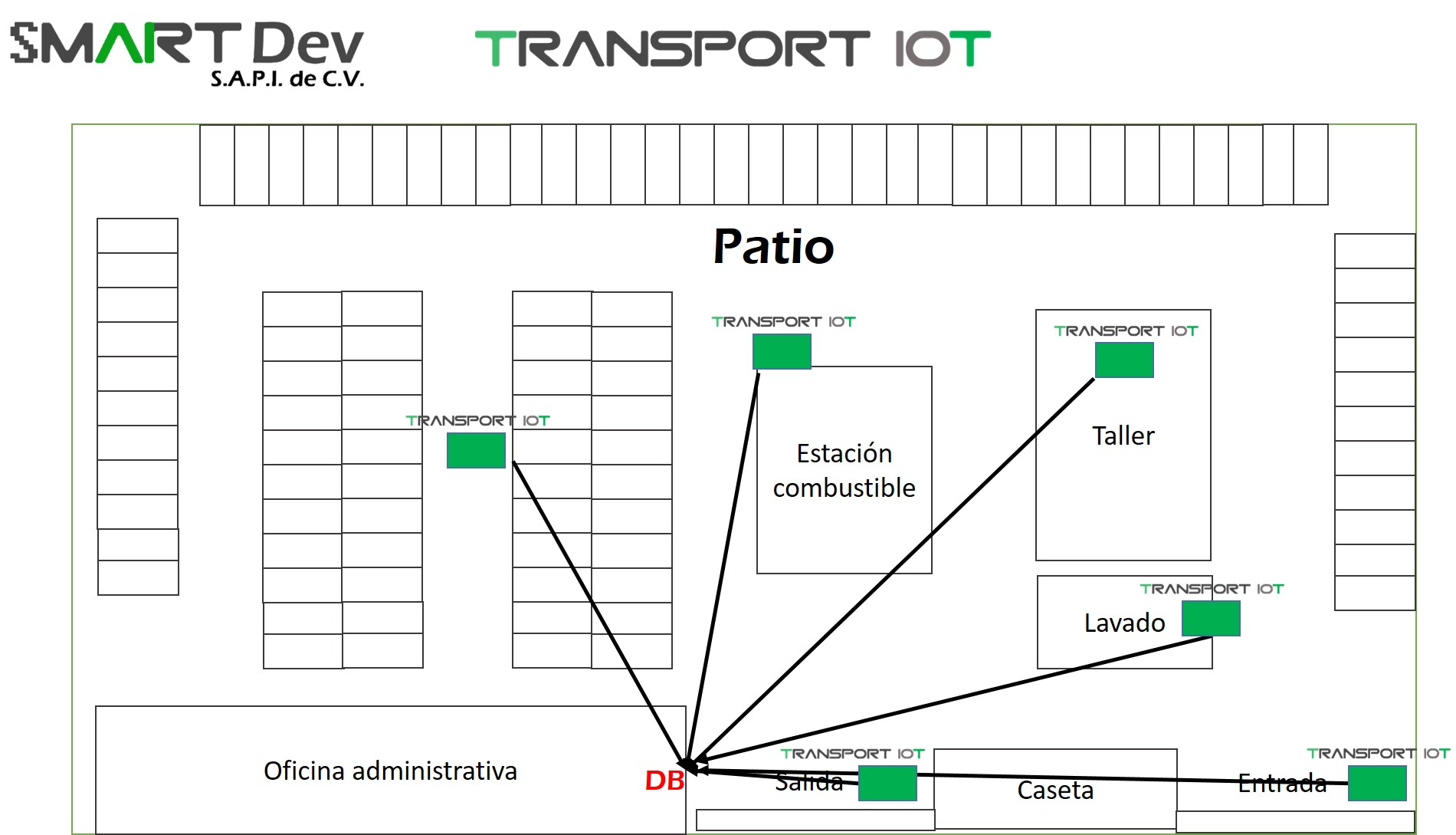

Is your operations yard producing many operating errors?

Our team analyzes, develops prototypes, tests, plans, and implements the best solution for your operation with:

Yard automation.

Access control.

Warehouse control.

Fuel control.

Integration of operational processes.

Statistical Dashboards.

Inspection Processes.

Our goal is to help you reduce human factor errors, waste, fines, improve process times and increase business profitability.

In addition to digitizing most of your processes that support you in complying with your ISO 9001-2021, OEA, CTPAT and STPS standards.